For car enthusiasts looking to enhance engine performance, forced induction systems like turbochargers and superchargers are popular choices. While both deliver significant power gains, they achieve this in fundamentally different ways, leading to distinct performance characteristics. Understanding the nuances of “Turbo Vs Supercharger” is crucial in selecting the optimal system for your needs.

Supercharger Mechanics: Instant Boost, Linear Power

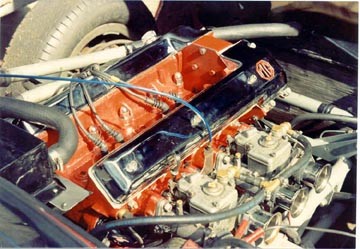

Superchargers are mechanically driven by the engine’s crankshaft, meaning they are directly linked to engine RPM. This direct connection results in boost that is proportional to engine speed. As the engine RPM increases, the supercharger spins faster, delivering a linear increase in boost. This characteristic provides instant throttle response and a predictable, linear power curve, often described as a “straight diagonal line” when graphed against RPM.

However, this constant connection also means the supercharger is always drawing power from the engine, even when boost isn’t fully utilized. This continuous parasitic loss can impact overall efficiency, especially at lower throttle inputs. While offering immediate power gains, superchargers can be less efficient in terms of fuel economy compared to turbochargers, particularly during cruising or part-throttle driving.

Turbocharger Dynamics: Spooling for Efficiency and Torque

Turbochargers, in contrast, harness energy from the engine’s exhaust gases. These gases spin a turbine, which in turn drives a compressor that forces air into the engine. This exhaust-driven operation is a key differentiator in the “turbo vs supercharger” debate. Turbo boost builds as exhaust flow increases, resulting in a boost curve that more closely resembles a typical engine power curve – a rapid increase in boost over a relatively short RPM range, followed by a flatter plateau at higher RPMs.

TVR race car on a track

TVR race car on a track

Alt text: Side view of a classic TVR race car speeding on a track, showcasing high-performance automotive engineering.

This characteristic often translates to superior low-end and mid-range torque compared to superchargers. Once “spooled up,” typically by around 2000 RPM, a turbocharger can generate substantial torque across a wider RPM band. Furthermore, modern turbochargers often incorporate wastegates. These valves regulate boost pressure by bypassing excess exhaust gas around the turbine when the desired boost level is reached. Crucially, during periods of low throttle or deceleration, the turbocharger effectively “bypasses” itself, reducing pumping losses and improving fuel economy. This on-demand boost capability is a significant advantage in the “turbo vs supercharger” comparison, offering both performance and efficiency benefits.

Why No Bolt-On Turbo Kits for Classic Engines?

Considering these advantages, the question arises: why aren’t turbocharger kits as prevalent as supercharger kits, especially for classic engines? The answer often isn’t technical feasibility, but rather market demand and development focus. Developing a bolt-on turbo kit requires significant engineering for components like exhaust manifolds, downpipes, and intake systems. While technically straightforward, as exhaust and intake ports are often on the same side of classic inline engines simplifying plumbing, the development cost and market size for specific classic car models may not always justify mass production.

Many turbocharger installations on classic engines have historically been custom, one-off projects. The absence of readily available, “bolt-on” turbo kits, unlike the supercharger kits popularized by companies like Moss Motors, is primarily due to a lack of commercialized, series production efforts.

The Untapped Potential of Turbocharging Classic Cars

The potential benefits of a well-engineered turbo kit for classic engines are substantial. Imagine a simple, comprehensive turbo kit, akin to existing supercharger kits, but delivering even greater performance gains. Such a kit would likely include a new exhaust manifold and downpipe, potentially paired with a draw-through carburetor setup for ease of installation and tuning. The market for such a kit, offering enhanced performance with potentially improved fuel economy, could be significant, particularly if priced competitively with existing supercharger options. As demonstrated by high-performance applications in modern supercars, the “turbo vs supercharger” debate often tilts towards turbocharging when considering overall efficiency and torque delivery. For classic car enthusiasts seeking a performance boost, the development of readily available turbo kits represents an exciting, and largely untapped, opportunity.